ZDPK-16032 (WC67K-160/3200) E200P CNC Press Brake

The model of this cnc press brake is ZDPK-16032 (WC67K-160/3200),with ESTUN E200P CNC control system.After input the backgauge value (bending position) and stroke data (bending angle) on E200P controller,the press brake ZDPK-16032 can run automatically;Different position and different angle can continuous program,it can save more than 70% time for the operator.With Y axis servo positioning function,it can accurate and effective improve Y axis accuracy and working efficiency.

● Strong rigid torsion bar design,ensuring the synchronous movement of ram stroke.

● Built-in mechanical stop,ensuring an accurate positioning of ram stroke.

● With E200P CNC controller,control the backgauge (X axis) and ram stroke (Y axis) run automatically,with easy operation,more output with less input.

● X axis is controlled by servo motor,with strong synchronous belt,with high control accuracy,fast positioning and low noise.

● The backgauge installed with ball screw and linear rail,with high repetition accuracy and low maintenance.

● Vertial movable stop fingers,they can not only slide on linear rail but also go up or down if needed,adapt to different moulds.

● With high-precision cnc moulds/dies and quick clamps,it will be more accurate and durable when bending plates,high efficiency when removing and changing upper punch tools.

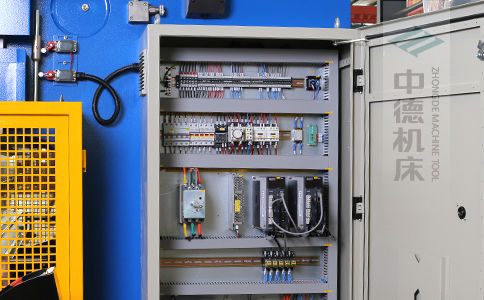

● With France Schneider electrics,stable and durable.

● With double front holder,can move horizontal.

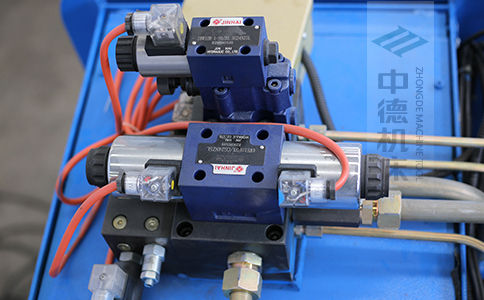

● With imported hydraulic system,stable and high precision when persistent working.

● E200P CNC controller for ZDPK-16032 CNC press brake

Main features of E200P controller:

CAN-bus mode to control servo system of X axis

Parts counting

40 programs saving,each with 25 sequences

One side positioning

Built-in time relay for cutting time and retrack

One key backup/restore of paremeters

Online diagnosis and real-time alarm

Reseved ports for safety guard

Color LCD bright display

mm/inch

Chinese/English

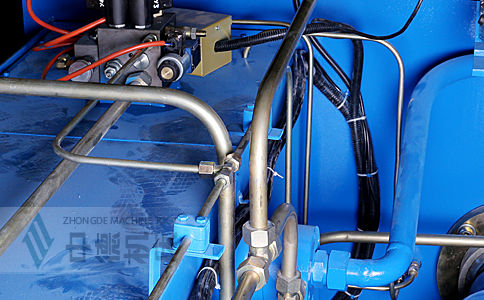

● Full-metal pipe shroud connection,nonexpansion when high temperature,can guarantee precision for long time.

● X axis with ball screw,linear rail,servo motor and steel synchronous belt,can improve X axis positioning precision and speed.

● High precision quick clamps,it is for easy operation of removing and changing upper punch tools.

● With France Schneider electrics,stable and durable.

● With imported hydraulic valve,stable and durable.

● Engineering switch,with long stroke control.

● Thicker type backgauge structure,adjustable stop fingers,they can not only slide on linear rail but also go up or down if needed,adapt to different moulds.

● With Y axis servo positioning function,it can accurate and effective improve Y axis accuracy and working efficiency.