16mm Cutting Thickness and 3200mm Cutting Length Hydraulic Shearing Machine ZDS-1632 (QC12Y-16X3200)

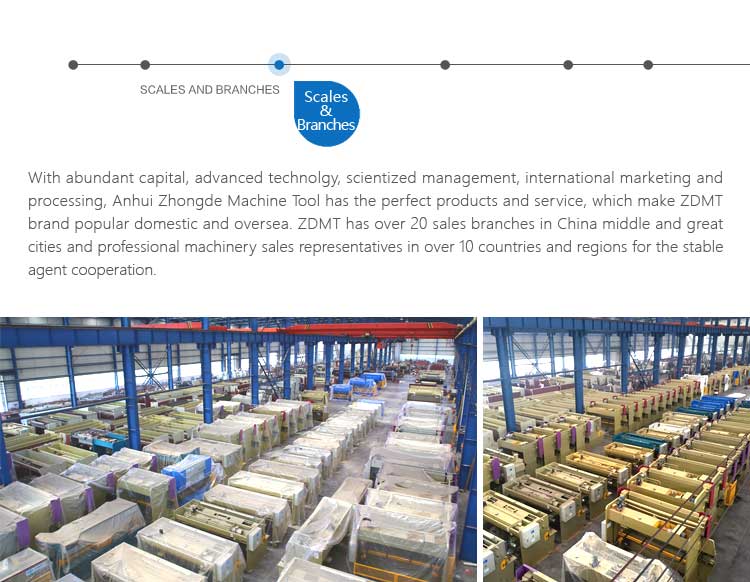

China Well-Known Trademark and Anhui Top Brand - ZDMT hydraulic shearing machine ZDS-1632 (QC12Y-16X3200),Steel plate welded structure,hydraulic transmission and accumulator return strock;Characterized by easy operation,reliable performance and fine appearance;E21S as the simple CNC controller,it can control the movement of backgauge,achieving efficient and highly precise positioning;The blades with high tensile strength,can cut mild steel and stainless steel;The maximum cutting thickness is 16mm and the maximum cutting length is 3200mm.

● Steel plate welded structure,hydraulic transmission and accumulator return strock.

● Characterized by easy operation,reliable performance and fine appearance.

● Indicator based gap adjustment of blades,convenient and swift.

● Shadow light alignment.

● Top blade could be adjusted for full stroke or shorter ones.

● Fence guard for personnel safety.

● E21S as the simple CNC controller,it can control the movement of backgauge,achieving efficient and highly precise positioning.

● E21S simple CNC controller for ZDS-1632 hydraulic shearing machine.

● Front view of ZDS-1632 hydraulic shearing machine.

● Rear view of ZDS-1632 hydraulic shearing machine.

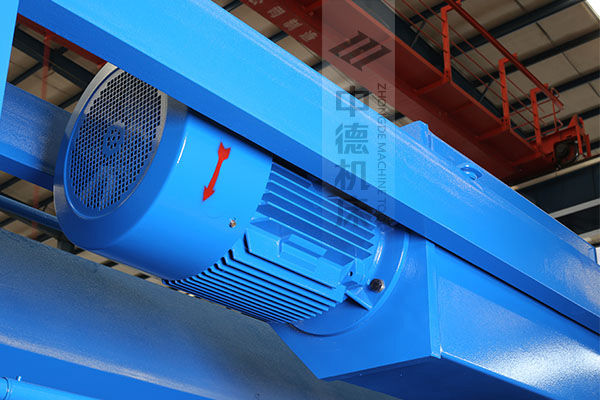

● Top brand main motor,with strong power.

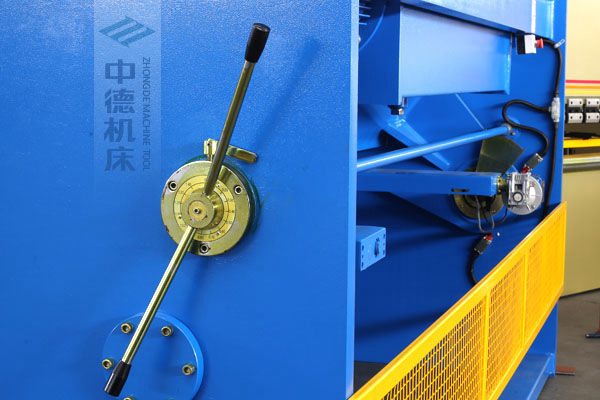

● Manual adjustment of blade clearance device,with high precision.

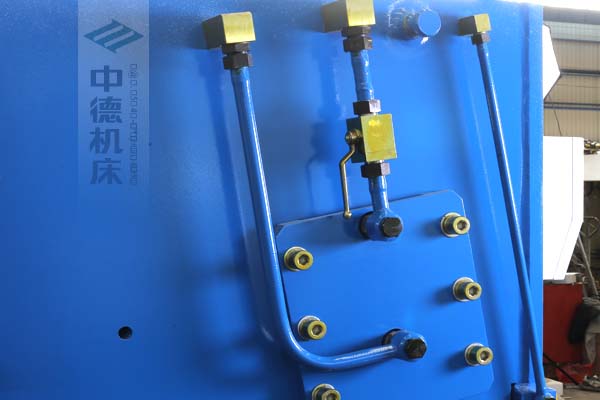

● Domestic high quality hydraulic valve,no oil leakage and fault,it can show the oil pressure in time,and it use full-metal high-pressure tube connection,ensure the quality.

● Penetration guard fence around the shear,not only protect the safety of operator but also observe the shearing position.

● Ball worktable can reduce the sheet metal contact with the workbench,reduce working intensity;Using high quality holding-down clamps.

● Shanghai good quality blades,with long lifespan.

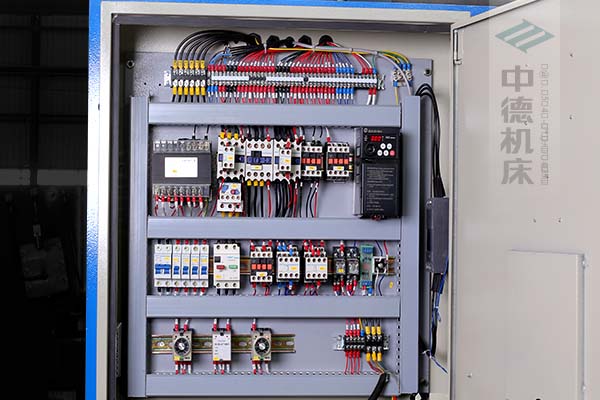

● Good quality electrics,with Taiwan frequency inverter drive,accurate control,stable,durable and long lifespan.

● Domestic high quality bearing,wearproof and long operation life.

● Using high quality holding-down clamps.

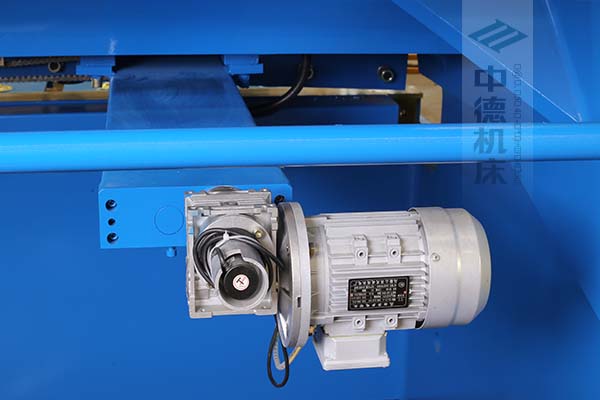

● Backgauge AC motor together with reducer,little fault and fast speed.

● Bite type tube fittings is used to avoid disadvantages of uneasy maintenance etc that caused by welding.

● Emergency stop button on the back of the shear machine,to protect the personnel safety.