ZDMT Work with Italy ESA to Develop the New Series of Synchro CNC Press Brake

Currently, ZDMT company develop the new generation of Hydraulic Synchro CNC press brake with the imported advanced CNC control system from the world famous supplier -Italy ESA company, This kind of machine is really welcomed by the market now. Many users and agents askss for quotation and the supply in order to expand their business and market.

The adopted Italy ESA S525 CNC controller has 7' wide LCD display screen and functions of quick one page parameters programming, form filling programming mode with real-time automatic checking, automatic bending pressure and compensation pressure calculation. Free entire off-line programming software ensures more convenient programming. All the parameters of programs and tooling can be saved in the system or USB flash disk, while can be uploaded to the other ESA CNC controller or PC. Tandem working with high performance, no need extra linkage card. 15 kinds of languages for user's selection.

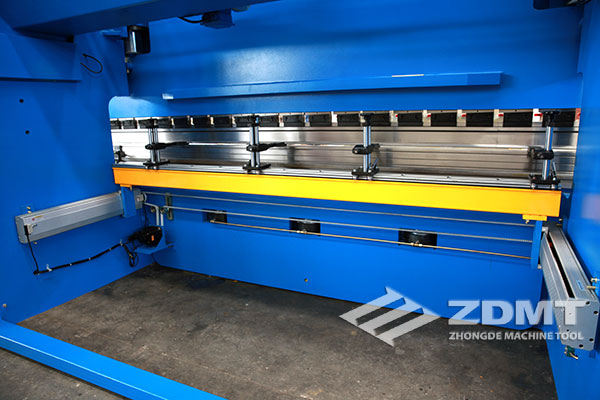

Except the ESA controller system, this type of synchro CNC press brake is installed with the imported Atos electrical hydraulic proportional valve to achieve the accurate parallelism between left and right cylinders, which brings high accuracy, fast speed of reaction and excellent edge-bending (offset loading) function. There are also double anti-deflection devices, one of which is by the compensation wedge of up slider and the other is by the crowing system on lower table. Both the devices will be against the deflection of slider and worktable to achieve the dead zone free compensation and high precision.

For future thinking, this series of ZDMT synchro CNC press brake will allow tandem working between two press brakes to do long parts bending. This is to say, another press brake of the same series can work with your current ESA press brake, no matter what the bending pressure and maximum bending length of the new press brake you will add in future. After that, the two ZDMT plate bending machines can work together for long parts. Meanwhile, each the press brake machine is able to work independently. It is really good for improve the productions efficiency.

This series of ESA Synchro CNC press brake machines are mainly installed with world famous parts: electrical hydraulic proportional valves (Italy Atos), electrics (Schneider), ball screws (Taiwan Hiwin), high pressure oil filter (German Hydac), low noisy internal gear pump (USA SUNNY), scale (Italy OPKON). All of those parts assure best cost performance.